White Paper

6 factors crucial to the success of industrial IoT in manufacturing

As manufacturers digitally transform their value chains, connected devices will play a major role.

Getting it right requires a laser focus on six key areas.

The internet of things (IoT) connects physical machines and equipment in a factory to the digital world of cloud, data analytics and artificial intelligence (AI). It enables you to collect more data, analyze the information quickly and make better business decisions.

Forward-thinking manufacturers already know they need to bring IT closer to operational technologies that control machines and equipment. Traditionally, these technologies were managed by separate departments in relative isolation.

Leaders, such as food and beverage giant Lion, have merged the teams to create a single integrated technology function to leverage synergies.

The next step is to harness technology to optimize the business and drive innovation. Industry 4.0 advances in manufacturing are setting the standard for creating the smart factory and supply chain of the future using industrial IoT (IIoT), analytics, cloud computing and cyber physical systems.

Manufacturers can now consider business model innovation and new revenue streams as they leverage the deluge of IoT data.

This is often called the servitization of the industry. The importance of Industry 4.0 and the IIoT is well understood, but how do you start implementing these concepts to maximize your chances of creating real value?

Critical success factors

Early discussions about IIoT primarily focused on the technology and what it could do, rather than on the business value IIoT could deliver.This is not surprising; IoT technologies’ cool factor has clearly captured people’s attention. More recently, the conversations have shifted to the variety of business benefits IIoT can deliver.

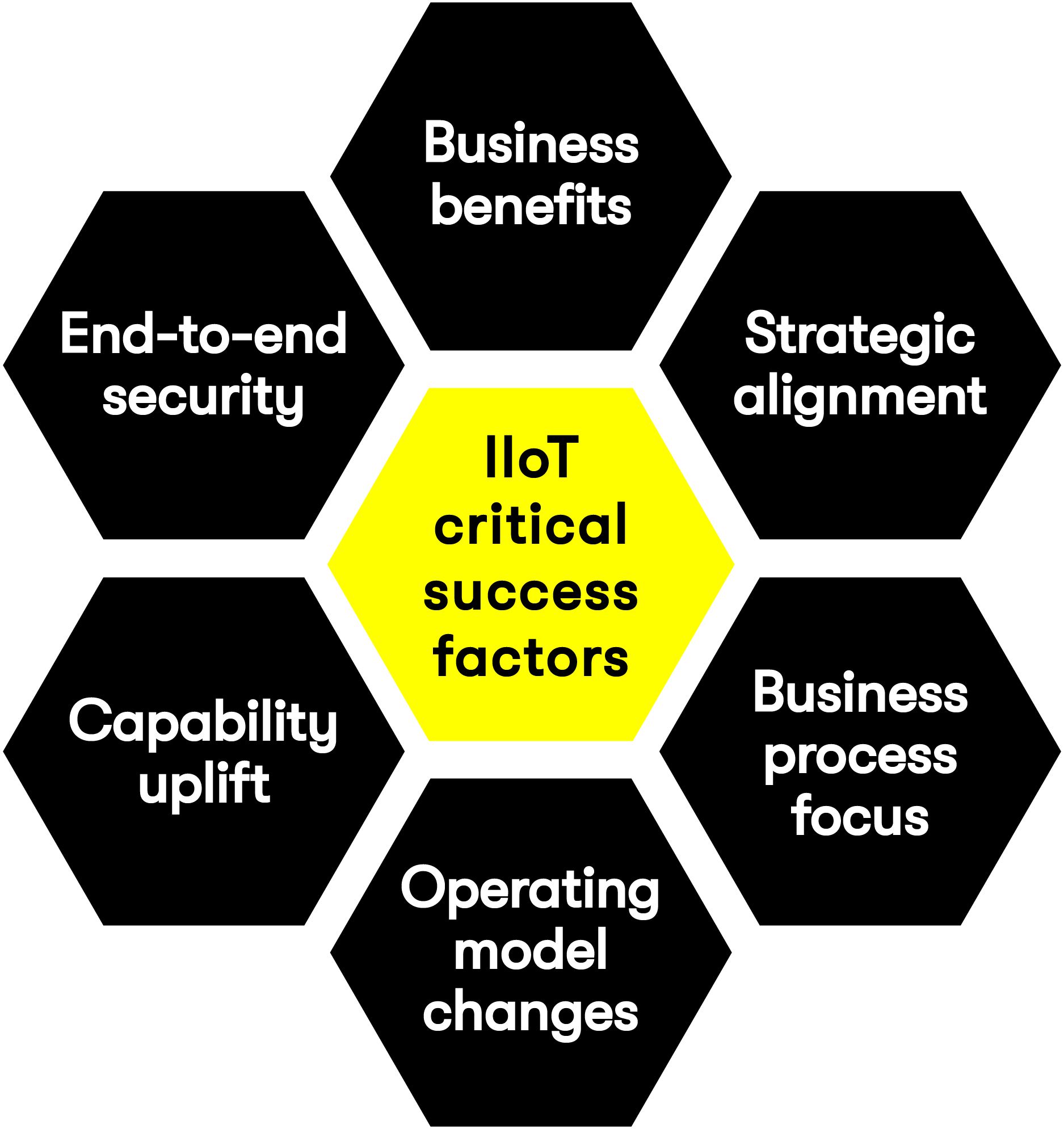

There are six critical success factors organizations need to consider to successfully use

IIoT in their digital transformation initiatives (Figure 1).

Strategic alignment

The business strategy provides guidance on goals and objectives, while the technology strategy identifies constraints around technology choices.

The best way to ensure strategic alignment is to create an IoT strategy that considers current strategies and also drives changes to those strategies.

For example, if IIoT provides a new way to ensure the health and safety of factory workers, the human resources strategy should consider this. Strategic alignment is key, but it is not a one-way street.

Some organizations have set up digital innovation labs without clear strategic direction or technology roadmaps, and the result is often proofs of concept that don’t have value for the business or are not supported by their technology functions.

For IoT to have a positive impact on the organization, it needs to be aligned with the overall business and technology strategy.

Business process focus

The discussion around IIoT is dominated by data analytics, machine learning and AI. Business processes may not be the most exciting topic, but they are still the core of any organization and define how the business operating model is structured. An emerging focus in the manufacturing industry is the integration of IIoT solutions into business processes.

In an IoT report, McKinsey notes that the missing integration of IoT solutions into existing business workflows is a top IoT capability gap.1

IIoT software vendors may claim their products integrate with business systems, but simply passing data to a business system is not the same as creating an end-to-end business process.

Using that process, organizations will have an increased number of smart things in their factory, increased levels of automation and more complex supply chains. The expectation is to make everything work together effectively in a way that is dramatically better than today.

Capability uplift

With changes to the technology landscape and operating model, employees need to learn new skills as their roles change.

It is important that people understand IIoT and Industry 4.0 concepts from both a business and technology perspective, establishing a common language to minimize the risk of misunderstanding.

For the next level of detailed understanding of IIoT, focused programs that advance employees’ capabilities need to be developed.

In these programs, active participation of the partner ecosystem, or value network, should be considered. A common learning experience can improve and drive day-to-day collaboration.

Consider how educational and training programs can affect certain roles in a manufacturing company and close skills gaps.

Chief operating officers can get new insights into the operation of the business, but they will want to understand what the new data is and how to incorporate it into their decision making. Chief technology officers will be flooded with new technologies and will want to select the ones relevant for the business.

They will want to learn about functionalities provided by IIoT gateways, low-power WAN, sensor boards and IoT platforms. Maintenance technicians will want to understand why predictive maintenance is important, and how IIoT and data analytics will enable them to be more proactive with maintenance inspection activities.

End-to-end security

Vulnerabilities in self-driving cars get a lot of media attention and illustrate the security concerns around IIoT. Smart factories are also at risk, and although technology vendors are quick to provide security patches, the risks show that security is often not built into the design of a production system. One of the reasons is that those solutions were closed systems for decades and relatively safe from intruders.

In the past, manipulating machines in a factory typically required physical access to the facility, but by linking assets to the internet and deploying IIoT capabilities, facilities are now exposed to new security risks.

New approaches for cyber-physical systems are being developed that include authentication and encryption capabilities built into hardware, real-time analytics of network traffic, and IIoT gateways that serve as protective shields for factory equipment, similar to the way firewalls perform in IT networks.

With the convergence of IT and operational technology, “security by design” is becoming a key decision criterion as companies choose technologies.

They will want to learn about functionalities provided.

About the author

Peter Klement is chief technologist for manufacturing in DXC Technology’s Digital Transformation Consulting, with a focus on Industry 4.0 and industrial IoT. His mission is to help organizations strategically transform their businesses with the help of digital technologies such as IoT, data analytics and cloud.

Peter looks at new technologies from the perspective of business benefits and how they can optimize operating models and foster business model innovation.

Hey friend! Please accept the terms of service agreement

Hey friend! You're already be subscribed

Welcome to the team! Using the keywords you gave us we promise send only relevant content.

Enjoy!

Stay informed with our latest updates.

Log in or create a free account to keep reading.

No subscribtion required